Using renewable energy rather than fossil fuel electricity in the smelting process to produce green aluminium is an easy technology. The change requires little or no changes in the aluminium production process. Aluminium, a very large industry, is known for its high demand of electricity to smelter the aluminium bauxite.

Existing Emissions With Simple Changes

Existing technology could immediately save over 50% without any technology changes. The change needs to be taken in various stages. Emissions could be reduced in very simple steps. Additional reductions may require some changes in production methods. Some smelters globally use hydro power, but most rely on fossil fuel energy sources.

Using Green Energy

Owners of aluminium smelters are changing their messaging. They now say they are moving to reduce CO2 emissions and moving to renewable energy as fast as possible. The aluminium owners previously resisted any change and they lobbied Governments hard against accepting any changes. (E.g. Comalco New Zealand Tiwai Smelter). Aluminium smelter owners are now seeking to reduce emissions using renewable energy as the first step. Different political landscapes call for different messaging, even though the technology does not substantively changed.

Rio Tinto stated (June 2021) its Boyne aluminium smelter, Yarwun Alumina refinery and Queensland Alumina refinery needed a combined 1,140 megawatts (MW) of reliable renewable power. Existing systems need 4,000 MW, or 4 GW, of wind and solar power backed up by energy storage. Companies have release tenders for suppliers. Green hydrogen with steady power for the manufacture of green aluminium is a first step.

Industry Has Resisted Green Aluminium

For the past 3 decades, aluminium smelting industry accounted for 16% of Australia’s carbon emissions from the electricity sector and 6.5% of Australia’s total emissions (excluding land-use change). (Australian Institute). Furthermore, they had large subsidies in electricity, estimated at $0.8 billion in 1999, despite 59% of the output of the aluminium smelting industry in Australia foreign owned, with Japan (17%), British (14%) and US (12%) interests dominant. Nothing much has changed in the past 2 decades.

Aluminum Manufacturing Processes

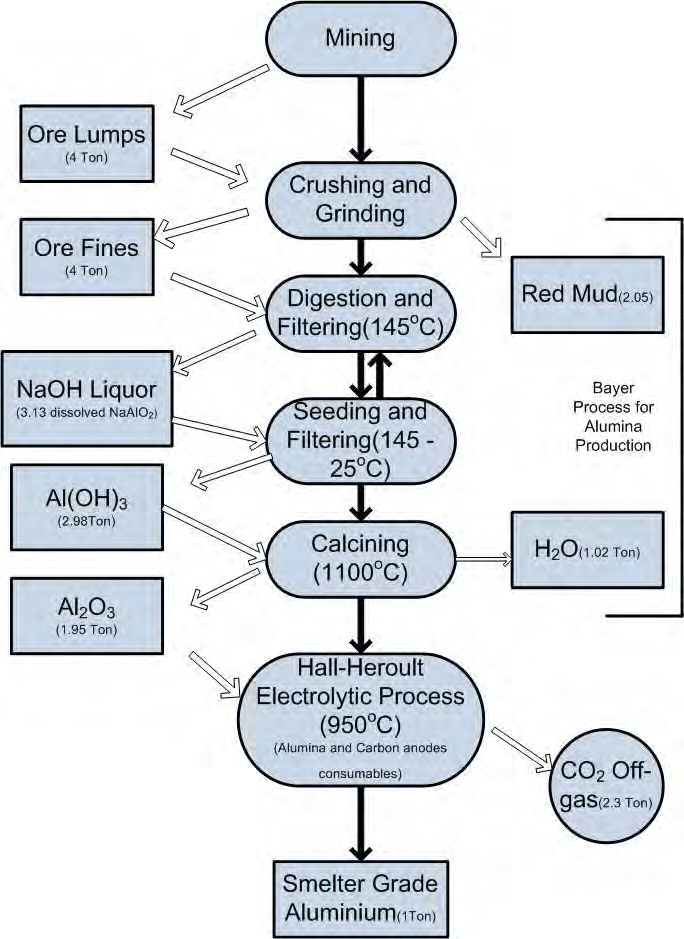

In “Impacts of aluminum production: A cradle to gate investigation using life-cycle assessment” (Science Direct), Farjana describes 4 steps:

- Mining of bauxite.

- Alumina production – using the Bayer process of refining the bauxite ore to obtain aluminium oxide

- Smelting – the Hall-Heroult process of smelting the aluminium oxide to release pure aluminium

- Ingot casting of the aluminium.

Green Aluminium Already Cost Competitive

In Australia, about 16% of the electricity used is for aluminium smelters. Replacing fossil fuel energy with renewable energy at both the mining stage and at smelting process reduces life cycle analysis emission and are the biggest and simplest changes.

The current average cost of producing aluminium using fossil fuels currently sits at US$1,680 per ton (A$2,156).

Production costs fall to US$1,590 per ton (A$2,040) with the combination of renewable energy sources and new “inert anode” technologies. The process has virtually no emissions from the aluminium smelting process. (Renew Economy 2021)

Two Simple Steps to Green Aluminium

- Use Renewable Energy in the Mining process. There are multiple existing technologies

- Change to renewable Energy in the refining, smelting and casting processes

More Difficult – Inert Anode in Aluminum Process

A more difficult process step is to replace the active anode with an inert anode. (See process from UN Climate Center) but Rio Tinto is already working on that as well in a pilot plant in Canada. (Press release Rio Tinto). The inert anode prototype cells will operate on a commercial scale typical for large modern aluminium smelters, using an electrical current of 450 kiloamperes (kA).

Aluminium Process Diagram