As batteries climb to higher density, shorter charging cycles the question is when will the 1000-mile battery innovations happen? Which company or research group will create the lab breakthrough that then is adopted into the gigawatt battery manufacture needed to power over 80 million EV cars each year?

In the article Lithium battery improvements key metrics for lithium ion batteries include

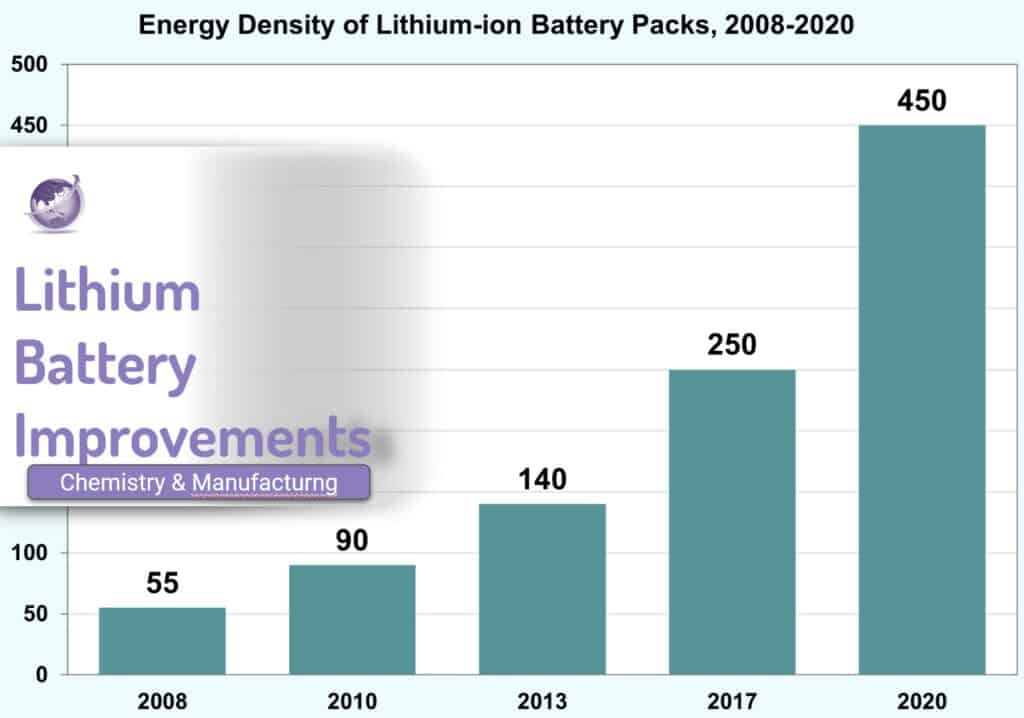

- Battery density Wh/kg – on trajectory from 300Wh/kg to over 700 in the lab

- Weight – a function of density

- Recharge cycles over lifetime. From 450 to 3000

- Lifetime – depends on degration over the ccles

- Speed of charging and discharge – called C value. C1 is 1 hour, C4 is 15mins

- Mechanical size, shape and stability – for installation in a car, grid store battery or consumer electronics

- Price

Keeping Track of 1000-Mile Battery Innovations

Weekly a new PR or report comes out about the latest innovation. Here are some examples.

“It is a given around the sauna and ice bath area at CleanTechnica that the batteries which will power our vehicles in 2030 are in the laboratories of today. We have no idea who will win the race to make those next generation batteries”

Steve Hanlen, CleanTechnica https://cleantechnica.com/2024/02/14/24m-claims-the-1000-mile-battery-is-nearly-here/

1. 24M

24M (https://24-m.com) in Jan 2024 announced the latest addition to its disruptive battery technology portfolio — Eternalyte™, a transformative new electrolyte developed specifically for lithium-metal batteries. The proprietary, liquid electrolyte formula will enable significant improvements in the cycle life and rate capability of lithium-metal batteries.

What will it do?

- Semi-solid system

- 391 Wh/kg

- 83% capacity over 500+ cycles, which is equivalent to more than 500,000 miles of total range.

- Expected to allow up to 1,000 miles of driving per charge.

- 4C charging

2. NREL Cathode

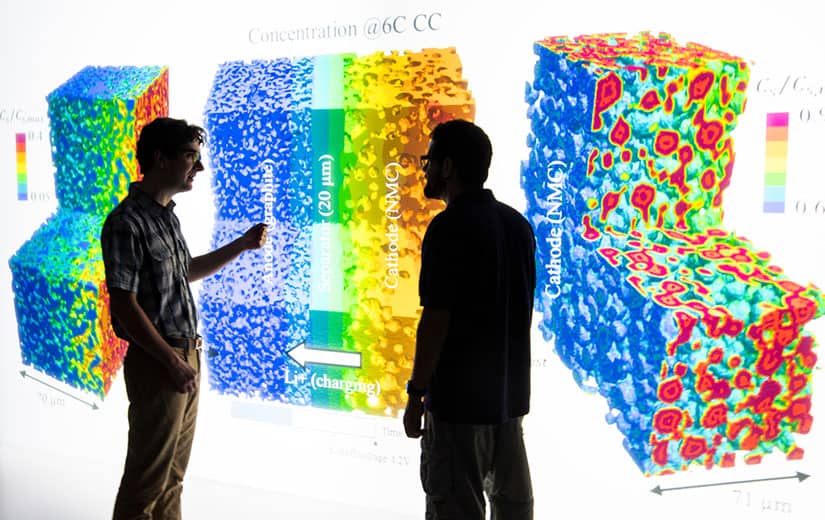

A news update on Feb 204 from NREL “Unleashing the Power: BatMan Project Revolutionizes Battery Manufacturing“. What have they done?

- Manufacturing enhancement using lasers which create intricate patterns of tiny holes in an electrode. This pore network unlocks battery improvements. These microscopic pores create access points to increase ionic diffusion, allowing the ions to move more quickly during charge and discharge without damaging the battery. As a manufacturing bonus, these pores also speed up electrolyte saturation during the wetting process.

- Nearly 100% more capacity after 800 cycles

3. Energy Density

Multiple researchers have demonstrated energy density.

More Reading

- 24M Claims The 1000 Mile Battery Is Nearly Here – CleanTechnica Jan 2024 https://cleantechnica.com/2024/02/14/24m-claims-the-1000-mile-battery-is-nearly-here/

- 24M – Company site 24-m.com

- NREL 2024 “Unleashing the Power: BatMan Project Revolutionizes Battery Manufacturing“.

- CleanTechnica 2023 Chinese Researchers Announce 711 Wh/kg Lithium Battery https://cleantechnica.com/2023/04/25/chinese-researchers-announce-711-kwh-kg-lithium-battery/

- Quan Li et al 2023A 700 W⋅h⋅kg−1 Rechargeable Pouch Type Lithium Battery Chinese Phys. Lett. 40 048201DOI 10.1088/0256-307X/40/4/048201