Green Methanol: A Potential Clean Fuel Solution is thought to be a possible solution to emissions reduction in shipping and aviation. Methanol, a simple alcohol with the chemical formula CH3OH, is now made using from fossil gas in a process with high emission levels. Green methanol holds significant promise as a clean fuel alternative with much lower emissions. Unlike traditional fossil fuels, green methanol production methods offer the potential to significantly reduce carbon emissions, making it a key player in the fight against climate change. Methanol is also made from biogas which is a lower emissions process, providing the biomass is sustainable.

The challenge is the cost. Fossil-fuel-based methanol is about $0.30/kg, and most green methanol processes rely on Hydrogen production and cannot meet that price. Innovation may.

Production Methods:

There are several ways to produce methanol, each with its own carbon footprint and technological challenges:

Fossil Fuel-Based

The traditional method involves steam reforming of natural gas or coal, resulting in significant CO2 emissions. This method currently dominates the market but is unsustainable for long-term climate goals.

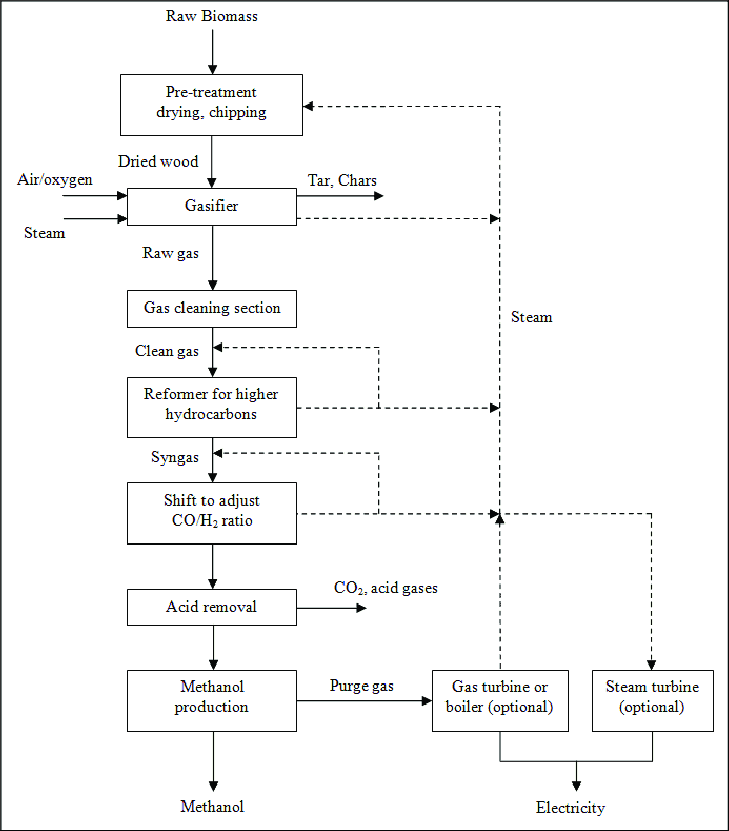

Biomass-Based (Biomethanol)

This requires sustainable biomass sources like woodchips, agricultural waste, or algae to produce syngas (synthesis gas), which is then converted to methanol. While emissions are lower than fossil-based methods, some emissions still occur during biomass growth and processing.

Direct Air Capture (DAC) and Renewable Electricity (e-Methanol):

This cutting-edge method captures carbon dioxide directly from the atmosphere and combines it with hydrogen produced from renewable electricity via electrolysis. The resulting syngas is converted to e-methanol. The process offers potential for negative carbon emissions if combined with efficient carbon capture and storage.

Pulverized coal gasification-integrated green hydrogen process

TLAs abound. The CTM process includes

- air separator (AS)

- coal gasification (CG)

- water-gas shift (WGS)

- acid gas removal (AGR)

- methanol synthesis (MS)

- distillation units (MD)

- power to hydrogen (PtH)

Potential Uses:

Green methanol boasts a wide range of potential applications, contributing to decarbonization efforts in various sectors:

- Transportation. Methanol fuel could power directly for ships, trucks, and even airplanes. Existing engines need slight modifications

- Chemicals and Materials: Methanol serves as a feedstock for various chemicals like formaldehyde, acetic acid, and olefins, enabling the production of sustainable plastics and other materials.

- Power Generation. Methanol is a fuel source in fuel cells for clean and efficient electricity generation.

Carbon Emissions and Trade-offs:

Each production method has its own carbon footprint:

- Fossil Fuel-Based: Highest emissions, contributing to climate change.

- Biomethanol: Lower emissions than fossil fuels, but still some emissions from biomass.

- e-Methanol: Potentially negative emissions if DAC is coupled with efficient carbon capture and storage.

Pros and Cons:

Here’s a quick comparison of the pros and cons of each method:

| Method | Pros | Cons |

|---|---|---|

| Fossil Fuel-Based | Established technology, readily available infrastructure | High carbon emissions, unsustainable |

| Biomethanol | Renewable feedstock, lower emissions than fossil fuels | Potentially limited biomass availability, land-use concerns |

| e-Methanol | Potentially negative emissions, versatile applications | High upfront costs, developing technology, DAC infrastructure needed |

The Road Ahead Green for Methanol: A Potential Clean Fuel Solution

Green methanol production is still in its early stages, but rapid advancements and investments are accelerating its development. Overcoming technological hurdles, expanding renewable energy infrastructure, and establishing efficient carbon capture and storage will be crucial for large-scale adoption. By addressing these challenges, green methanol has the potential to revolutionize various industries and play a vital role in transitioning towards a low-carbon future.

Remember, choosing the most sustainable method depends on various factors, including regional resources, technological maturity, and infrastructure availability. A combination of approaches might be necessary to meet future fuel demands while minimizing environmental impact.

References

- Dongliang Wang, Wenliang Meng, Huairong Zhou, Yong Yang, Jiangpeng Xie, Siyu Yang, Guixian Li, 2022 Novel coal-to-methanol process with near-zero carbon emission: Pulverized coal gasification-integrated green hydrogen process, Journal of Cleaner Production, Volume 339, https://doi.org/10.1016/j.jclepro.2022.130500.