In an interview in Autoline on 19th January, Matthew Vachaparampil of Caresoft was asked can legacy Automakers catch Tesla. His conclusion is no. Chinese manufacturers are more willing to follow Tesla’s lead with innovative design and manufacture. The essential components include:

- Weight. Every kg means less battery (cost) and more range.

- Component number. Reduces factory capital investment

- Smart Systems. Reduced labour costs, lower cost of goods

The EV market is rapidly expanding with Tesla and BYD as leading auto manufacturers.

Eightify summarises the interview. Tesla’s innovative and efficient manufacturing process challenges traditional car assembly. It forces legacy automakers to adapt quickly to new technologies and design principles. If they do not adapt they lose competitiveness in the electric vehicle market.

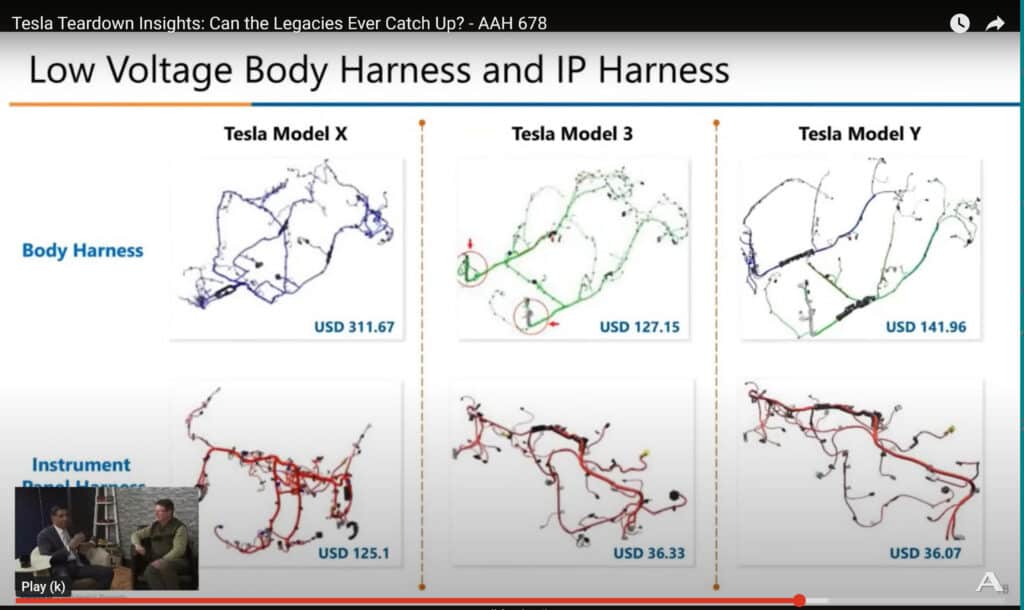

Screen Grabs from Video

Key insights

- The journey to the $25,000 EV is a less complex car. More modularity, more automation is like building a car with Lego blocks.

- Tesla thinks like an iPhone, making rapid changes and improvements, unlike the traditional auto industry mindset.

- Tesla is still the top benchmarked company for the Chinese, even ahead of other oems like Volkswagen and GM.

- Tesla’s approach to vehicle design is from a total system standpoint, not from discrete components or silos within the company.

- Legacy OEMs in other countries tend to give reasons why something cannot be done. The Chinese companies have an openness to try something new without shooting down ideas.

Q&A – Can Legacy Automakers Catch Tesla

| Q&A | Answer |

|---|---|

| What is Tesla’s approach to manufacturing electric vehicles? | Tesla’s approach involves splitting the vehicle into separate modules for more efficient assembly, reducing plant investment and process time through modular build, automation, and Giga castings. |

| How does Tesla’s manufacturing process challenge traditional car assembly? | Tesla’s manufacturing process challenges traditional car assembly by rethinking the process and focusing on reducing parts, weight, complexity, and cost to make EVs more affordable and profitable for companies. |

| What is the impact of Tesla’s manufacturing process on other automakers? | Tesla’s approach involves unboxing the body, enabled by Giga castings and battery stiffness, to meet crash requirements and ensure safety, which is a departure from traditional methods. |

| How does Tesla’s approach to constructing electric vehicles differ from traditional methods? | The key to survival for legacy automakers is to learn and adapt quickly to the new technologies and design principles of electric vehicles to stay competitive. |

| Tesla’s manufacturing process is forcing legacy automakers to adapt quickly to new technologies and design principles to stay competitive in the electric vehicle market. | The key to survival for legacy automakers is to learn and adapt quickly to the new technologies and design principles of electric vehicles in order to stay competitive. |