Ten cybertruck features disrupting the vehicle market have been widely discussed on social media following the launch and reviews. The Tesla CyberTruck was announced in Nov 2019, with the first 10 deliveries to customers at the launch day on Dec 1st 2023. Either you like the shape, reminiscent of the DeLorean vehicle from 1981 or suitable for Mad Max movies or you don’t. The top ten cybertruck features were chosen from multiple improvements and demonstrate future vehicle manufacturing. There are many commentaries out there already, but this is my pick.

There will be some customer deliveries in 2023. The videos of the existing manufacturing line suggest a rate of ~100 per day. The official Tesla production figure is rising to 250,000 per annum over 18 months in 2024/2025, as they scale up production. Some suggest demand will be more than 500,000 million a year, focused on a market that has over 3 million pick-up trucks sold pa.

- Stainless Steel External panels

- Gigacasting of frame

- 48-volt wiring

- Steer by wire

- Replacement of CAN Bus with a POE bus

- Vehicle to Load Electricity

- Electric Motor

- Safety

- Manufacturing Automation

- Comfort

Real Story is the “Model 2” Small Sedan / Robotaxi

My view (and others) is that the Cybertruck is the stepping stone in manufacturing to producing over 6 million small sedan / Robotaxis by 2026/27. The technology changes enables Tesla to sell the Cybertruck at a similar price to current large USA pick-ups, with good margins. While the low spec F150 etc is $39,00, full-trim ICE trucks are over $US73,00 (Cybertruck $69,900). All of these ten innovations below will be incorporated into a small sub $US25,000 car for manufacturing at scale.

1. Stainless Steel External Panels

The stainless steel panels are up to 3 mm (1⁄8 in) 30x series (supposedly 30x – or HFS) cold-rolled stainless steel body panels, which cannot be stamped like conventional automobile parts, but instead are laser-cut and then bent along straight lines, resulting in a faceted design that has been called “low-poly” and likened to origami. Repelling a 9mm tommy gun/pistol in panels or windows along SEPA grade filtering is going to make this vehicle suited to military or police duty. Eliminating most of the welding simplifies manufacturing.

Moreover, the painting of cars is the major environmental issue with auto plants and is about 30% of the cost of vehicles.

2. Gigacasting of Frame

Much has been made of the front and rear subframes, made with a 9,000-tonne gigacasting out of proprietary aluminium, saving hundreds of robots and providing sub-millimeter accuracy and reducing variability. For more information, check out this post on Autopian.

- The front casting is made by the 6,000 tonne using the same tool as the model Y

- The rear is so big that there are 9,000 tonne press

- Integrates the crash can into the casting

- Reported Tesla has 3 x 9,000 tonne presses, with a capacity of 166,000 per machine, so 250,000 production is possible by mid 2024 (Luca Greco on X)

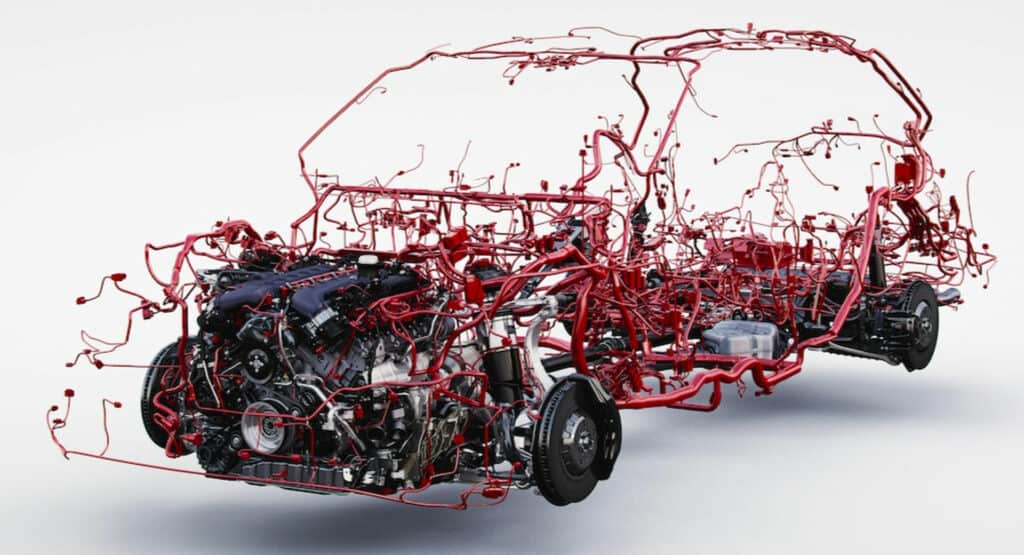

3. 48-volt Wiring

Six-volt wiring was in automobiles until the 1950s. Some buses and trucks use 24v, but with the Cybertruck at 48v, the wiring could be reduced by 4 times for the same power. Moreover, the move from the CANBus to the POE bus as well as the 48-V, enables steer-by-wire.

The 48V enables brakes change from hydraulic to electrical, eliminating the wholes system of hydraulic/electric pumps, hoses, and brake systems. It may be that the suppliers could not deliver electric brakes in time, but could be changed in a subsequent product revision.

48V will ultimately lead to other systems changing to electricity. The Grid-to-Load is enabled by the 48V architecture.

Tesla forwarded a handbook document on How to Design a 48V system to other automakers.

Great to read the document and realize that our next-gen team has been on a similar path. Let’s work together to help the supply base move into the 48V future as well.

Jim Farley, CEO Ford. https://x.com/jimfarley98/status/1732821715032375493?s=20

4. Steer by Wire

The first pure electronic fly-by-wire aircraft with no mechanical or hydraulic backup was the Apollo Lunar Landing Training Vehicle (LLTV), first flown in 1968, and aeroplanes followed. The Concord was the first in 1969. All planes are now fly-by-wire. Few auto manufacturers have used steer-by-wire and most still use mechanical or power-assisted systems. Steer-by-wire enables all-wheel steering.

- 9 to 10O steering on rear wheels

- 340 degrees lock to lock

Four-Wheel Steering gives Cybertruck a tighter turning radius than a Model S

— Cybertruck (@cybertruck) December 5, 2023

At low speeds, rear wheels rotate opposite to the front wheels—enabling tighter maneuvering around the jobsite, parking lots, etc pic.twitter.com/nxDiRTZKEI

5. Replacement of CAN Bus with a POE bus

The Controller Area Network (CAN bus) is a message-based protocol designed to allow the Electronic Control Units (ECUs) found in today’s automobiles and other devices to communicate with each other in a reliable, priority-driven fashion. The bus only operates at kilobit speeds and was designed for “noisy” environments such as high voltage spark plugs. Key points are

- Tesla replaced the CAN bus with a Tesla-designed Power Over Ethernet (POE) bus.

- Bi-directrional for redundancy GMA network time sliced rather than an ethernet so no latency.

- In the Model 3, there were 273 devices and 490 wires. In the Cybertruck, 368 devices but only 156 wires.

- 84% reduction in weight of high power harness wires

- 83% of peak power comes from 13% of devices

- Cables go to endpoints, not to intermediate controllers

- Advantage is debugging software much easier with a single bus. Much more homogenous. Have a software-defined network, not a hard-wired

- 48V is already used to provide power in POE at gigabit speeds.

- POE is a globally and widely -deployed bus in every data centre, every business and every home and the Internet of Things (IOT) ranging from high-definition video, and audio, to low-speed sensors.

- High-definition sound flow around the car. Microsecond speed and allows microphones to provide noise cancellation to all speakers.

- Video systems no longer require thick, insulated audio cables and run on ethernet cables or fibre.

- Enables control of every device from brakes to sound system to lights to be all operated on the same system and the 48V is sufficient for high electrical loads as well.

6. Vehicle to Load Electricity

Tesla has been slow to implement vehicle-to-load or vehicle-to-grid into their cars – mostly as they do not want to cannibalise their inverter/battery storage Powerwall market. The Cybertruck has a 11.5kW / 124kWh capacity with 11.5kW bidirectional charging, and 110V /240V outlets in the cabin and in the truck tray. Tesla’s announcement “Tesla vehicles* equipped with Powershare technology have onboard electronics that unlock your battery’s ability to provide power whenever you need it, wherever you are. Whether you need to power a construction site, pre-game tailgate, another electric vehicle or even your home during an outage, your Tesla vehicle with Powershare has you covered.”

Tesla announced an extra battery, service centre installed, available by end 2024 to extend range by 50+miles to close to 500 miles, or for better miles if towing. It’s a smart move – Tesla will have data that says 350 miles (550km) is the “Range Anxiety” distance. They have figured out for 80% 350 is adequate – keeps costs down and they have no shortage of customers.

7. Electric Motors

The Tesla electric motors have generally been shared across models – the Model S electric battery powers the Semi. For this, Tesla has introduced a single/dual motor – in a single housing along with the offroad/differential lock. So the standardisation on all the components. The rear wheels have steering, allowing better-turning circles and road handling. The amount of rare earths is less in the Cybertruck than the Model 3.

Provides 8-60 miles per hour in 2.6secs

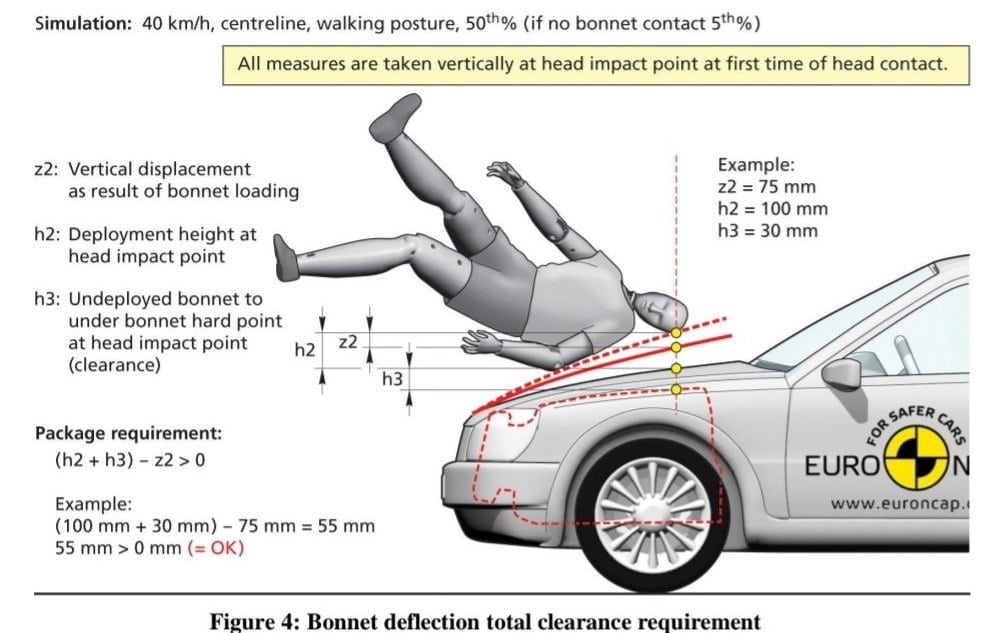

8. Safety

One comment was that virtual safety testing in a model reflects real-world crash tests, enabling safer vehicles for drivers, passengers and others. The best accident is no accident. The first models of the vehicle come with full FSD driving. FSD anticipates potential accidents even from the side (most driver assist software handles front and rear impact, FSD anticipates side collisions such as red light running).

Regulation (EC) No 78/2009 of the European Parliament and of the Council (9) sets out requirements for the protection of pedestrians, cyclists and other vulnerable road users in the form of compliance tests and limit values for the type-approval of vehicles with regard to their front structure and for the type-approval of frontal protection systems (for example, bull-bars). Since the adoption of Regulation (EC) No 78/2009, technical requirements and test procedures for vehicles have developed further at UN level to take account of technical progress. UN Regulation No 127 laying down uniform provisions concerning the approval of motor vehicles with regard to their pedestrian safety performance (‘UN Regulation No 127’) currently also applies in the Union in respect to type-approval of motor vehicles.

The EU has regulations on pedestrian safety (as most large pick-up trucks and SUVs are lethal to pedestrians and cyclists. Some commentators say the Cybertruck with its “light-truck” classification won’t be legal in Eu (https://www.motoringresearch.com/car-news/tesla-cybertruck-production-europe-news/) while others suggest otherwise. TBA.

For the driver and passengers, Tesla claim their virtual safety simulation is as good as actual testing, so expect even higher safety ratings.

9. Manufacturing Automation

Visitors to the launch said what struck them was the lack of people. Musk has claimed that the product line is the most automated car assembly line in the world. The design of the plant demonstrates that designing out parts has led to fewer stations on the main line. Spurs off the main line enable subassemblies. With no exterior paint, processes can be reorganized for efficiency.

- The controller boards are mounted on the firewall, and also have connectors on wet side to the dry side, eliminating grommets.

- The power conversion systems is next generation. Everything surface-base full flow. More efficient.

- Battery can be charged at either 400V or 800V

The assembly line is close by the new model 2 line, and every improvement on the Cybertruck line will be directly added to the Model 2 line.

10. Comfort and Miscellaneous Improvements

Designing from first principles enabled a raft of subtle but substantial improvements. From a useful frunk, accessories, removal of rear vision mirrors, more powerful lights, the largest glass in a vehicle, the largest windscreen wiper, fold-up rear seats, no door handles the list is extensive.

Things the Cybertruck went into production with in 2023 that we didn’t know about/expect during the original 2019 unveil: (from Sawyer Merritt on X https://x.com/SawyerMerritt/status/1732877239006466209?s=20)

Positives

- 17.44″ ground clearance (16″ exp)

- 4680 structural pack

- 48-volt electrical system

- Steer by wire

- Rear-wheel steering

- Pressured battery feature for driving through water (Wade Mode)

- PowerShare (charge another Tesla/power your home)

- 0-60mph in 2.6s (2.9s exp)

- Powered frunk

- 240v outlet (220 exp)

- 11,000 tow rating for dual motor (10k exp)

- Home Energy/Virtual Power Plant integration

- Range extender for RWD and AWD trims (coming soon)

- Front bumper camera with integrated washer

- Rear screen for passengers

- Katana wiper

- No door handles

- 340 mile range for Dual-Motor AWD (~300 expected)

- 350kW charging capability

Negatives

- Pricing much higher than expected

- 320 mile range Tri-motor (500 exp). Range extender is available that brings it to 440 miles but it’s $16k.

- No integrated tailgate ramp

- No integrated air compressor

- No 6 seat option

- No sail panel storage

- 223.7″ length (vs 231.7″ exp), though some people might prefer that

- No integrated light bar under glass

- Up to 2,500 lb payload (3,500 lb expected)

- Up to 11,000 lb towing (14,000 lb expected)

Acknowledgements and Further Reading

I acknowledge the original comments from a range of Tesla commentators. There are a large number of enthusiasts

- Cern Basher https://x.com/CernBasher/status/1730337217237684703?s=20

- The Limiting Factor

- Dr KnowItAll Cybertruck STEER-BY-WIRE Is THE FUTURE–But How Does It Work?! https://youtu.be/BDxbHZ_MMks https://x.com/DrKnowItAll16/status/1730977804601221509?s=20

- Dr Know-it-all Factory EXPERT Reveals Tesla Cybertruck FACTORY SECRETS!! With Scott Walter https://youtu.be/AT5ljiXbDOc

- Sawyer Merritt https://x.com/SawyerMerritt/status/1732877239006466209?s=20