Boston Metal is a pioneer in the production of green steel with the molten oxide electrolysis process to reduce iron ore to steel. Using electricity only, the only emissions are oxygen. Boston Metals has been developing this for over 12 years and has a number to go.

The reduction process produces the majority of emissions in steel production. The reduction process with iron ore and coal occurs with heat in a blast furnace to strip the oxide from the iron ore.

Note there are emissions from mining, transportation prior to reduction, then emissions in the forming and production processes.

Molten Oxide Electrolysis by Boston Metals

Boston Metals has developed an electrolysis process that eliminates the need for coal in steel production. They use renewable electricity to convert all iron ore grades to high-quality liquid metal. This direct approach eliminates several steps in the steelmaking process and does not require coke production, iron ore sintering and pelletizing, blast furnace reduction or basic oxygen furnace refinement.

The process takes place in a MOE cell. The inert anode is immersed in the electrolyte which contains the iron ore. High electrical currents increase cell temperature to 1600°C. At that temperature, electrons split the bonds in the iron oxide in the ore, producing pure liquid metal. There is no carbon dioxide or other harmful byproducts generated.

There is no waste. The only product is oxygen from the FeO, and the process needs no water, no hazardous chemicals, and no precious-metal catalysts.

Further processing of the clean, high-purity liquid metal uses conventional ladle metallurgy. Reheating is not required.

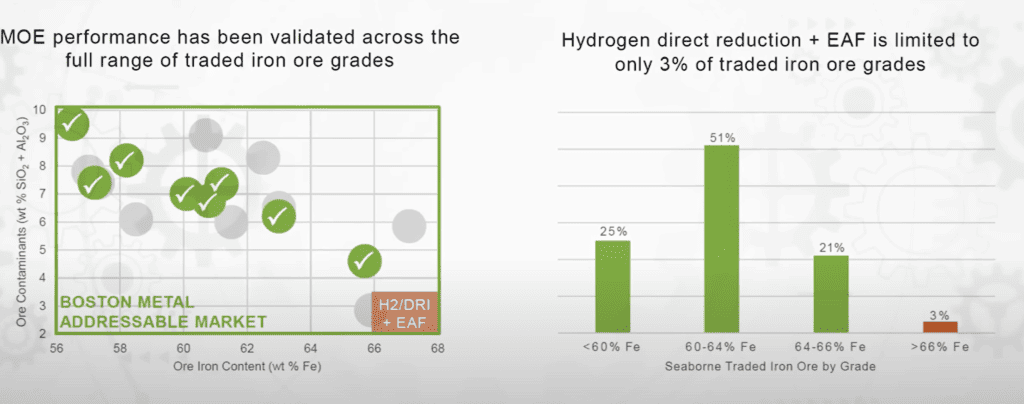

Multiple Ore Sources for MOS

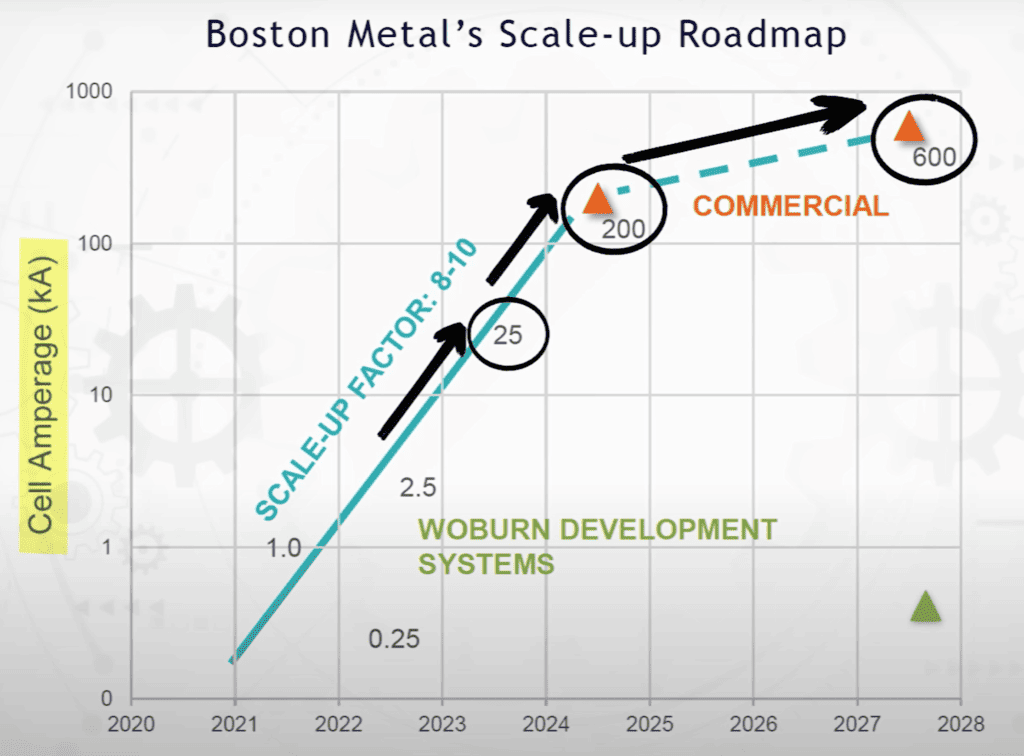

Scaling of Process to Commercial Use

Decade Long Development

Will DRI Be Cheaper than MOS?

Will the added expense to make green steel be acceptable to reduce carbon emissions? It is probably too early to tell, so watch this space.

Green hydrogen is too expensive to use in our EU steel mills, even though we’ve secured billions in subsidies

Geert van Poelvoorde, head of ArcelorMittal’s European operations Hydrogen Insight 2024

More Reading

- CO2-Free Fe: Green Steel Tour with Boston Metal Engineering with Rosie CO2-Free Fe:YouTube https://www.youtube.com/watch?v=GJKoBgBCPW0

- New breakthrough claims 90% reduction in Steelmaking emissions. Just have a think YouTube https://www.youtube.com/watch?v=eX80JkuzfTE