The use of hydrogen battery storage is being considered or even promoted as an economically viable alternative to lithium ion batteries or pumped hydro. As this is new technology, there are many unknowns. Hydrogen as a fuel for light vehicles is unlikely, but green hydrogen for other uses such as an alternative to grey hydrogen or green steel make sense. The challenge is storage and transport.

Conclusion: Hydrogen Battery Storage is Economic

- The cost of a hydrogen electrolyzer is reducing to about $300kW (or $3m MW), but the plant works for 10 years.

- Hydrogen produced costs about $3 to $4 per kg, and within a few years will be less than $1kg

- The purchase price of PV or renewable energy is about $30 MWh

- The sell price of energy at peak time is $300 MWh, so the margin is about $270 per MW

- The energy from 1kg of hydrogen is 33 kWh

- The battery would operate supplying electricity for 876 hours (based on independent modelling for a 100% renewable grid)

- Based on this data, batteries would make economic sense

- Unknown is the cost of storage and transport. If the renewable energy source, H2 creation, and H2 burning were co-located at the same site it makes sense.

- Must read is Yates et al 2020 paper https://www.cell.com/cell-reports-physical-science/pdfExtended/S2666-3864(20)30224-1

Economic Assumptions

| Hydrogen Battery | High-Cost Scenario | Low- Cost Scenario | Notes |

| Electrolyser Cost | $1,200,000 | $300,000 | Per MW as per IEA |

| Cost to produce 1kg H2 | $5.00 | $1.00 | Cost of H2 per kg |

| Energy in 1 kg | 33 | 33 | kW energy in 1kg |

| Conversion to electricity | 60% | 90% | Efficiency burning to electricity |

| How many kg H2 for 1MWh | 30 | 30 | |

| Cost per MHh H2 | $253 | $34 | |

| Energy differential | $270 | $270 | Buy RE energy at $30, sell $300 MWh |

| Margin | $17 | $236 | After cost of Renewable energy |

| Hours per year | 600 | 1,000 | Usage – model estimates 876 annual |

| Hours in 10 years | 6,000 | 10,000 | Total offer 10 years |

| Profit | $104,848 | $2,363,300 | Inclusive of costs of capital and opex |

IEA (2019) provides a breakdown of capital costs by electrolyser type. For alkaline electrolysers they are between A$714-2000/kW (today) and A$571-1214/kW (2030)

IEA (2019) provides a breakdown of capital costs by electrolyser type. For alkaline electrolysers they are between A$714-2000/kW (today) and A$571-1214/kW (2030)

Gladstone Green Hydrogen / Ammonia Plant

Ammnia production is the focus of the $4.7B Gladstone project.

- 3 GW of electrolysis

- Planned production up to 5,000 tonnes of green ammonia a day.

- Powered by 100% renewable energy

- New-build solar and wind.

- Theoretically 177 kg of H2 and 823 kg of N2 produce 1 tonne of ammonia.

Analysis of hydrogen battery storage

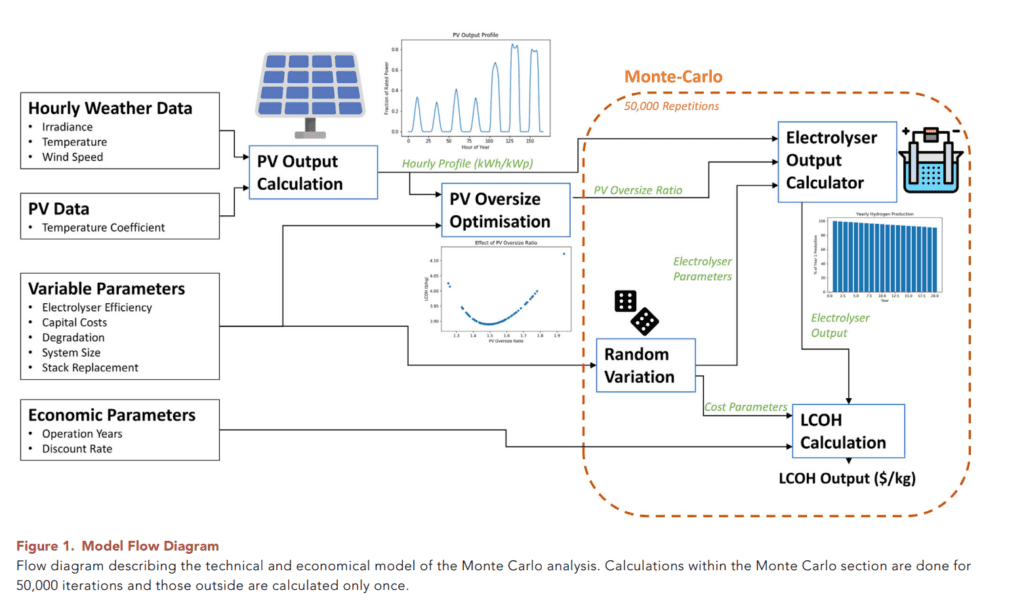

A detailed study by Yates et al from the University of NSW called Techno-economic Analysis of Hydrogen Electrolysis from Off-Grid Stand-Alone Photovoltaics Incorporating Uncertainty Analysis in Cell Reports provides a deep analysis of various factors.

Factors Important in Generating Hydrogen

(A) LCOH histogram and breakdown for the base case of Townsville. Purple lines indicate the estimated range for grid-connected electrolysis in the National Hydrogen Roadmap 6 (top).

(B) Bars in the breakdown graph represent the 10th and 90th percentiles for each component (bottom).

Key Messages from Hydrogen Battery Storage and Generation

- Capex cost is about 1/2 the cost of H2. If electricity source is from the grid, building your own PV has no value that buying from the grid at low price.

- A major cost is the Electrolyzer . Utilisation therefore determines profitability. But if the capital cost reduces by 10x, then it becomes a small cost even with low rates of H2 production to match cheap power.

- The operating cost of PV and electrolyzer is minor

What comes clear that if the cost of PV capex and PV opex is very small or negative, as what is happening with energy surplus in the middle of the day then the costs become small.